Recovery of individual polymer types

Solvent-based recycling makes it possible to recover recycled plastics with the properties of virgin material. The process is applicable to a wide range of mixed materials such as composites and contaminated post-consumer waste because contaminants and additives are being effectively removed from the target material. This makes our solution unique.

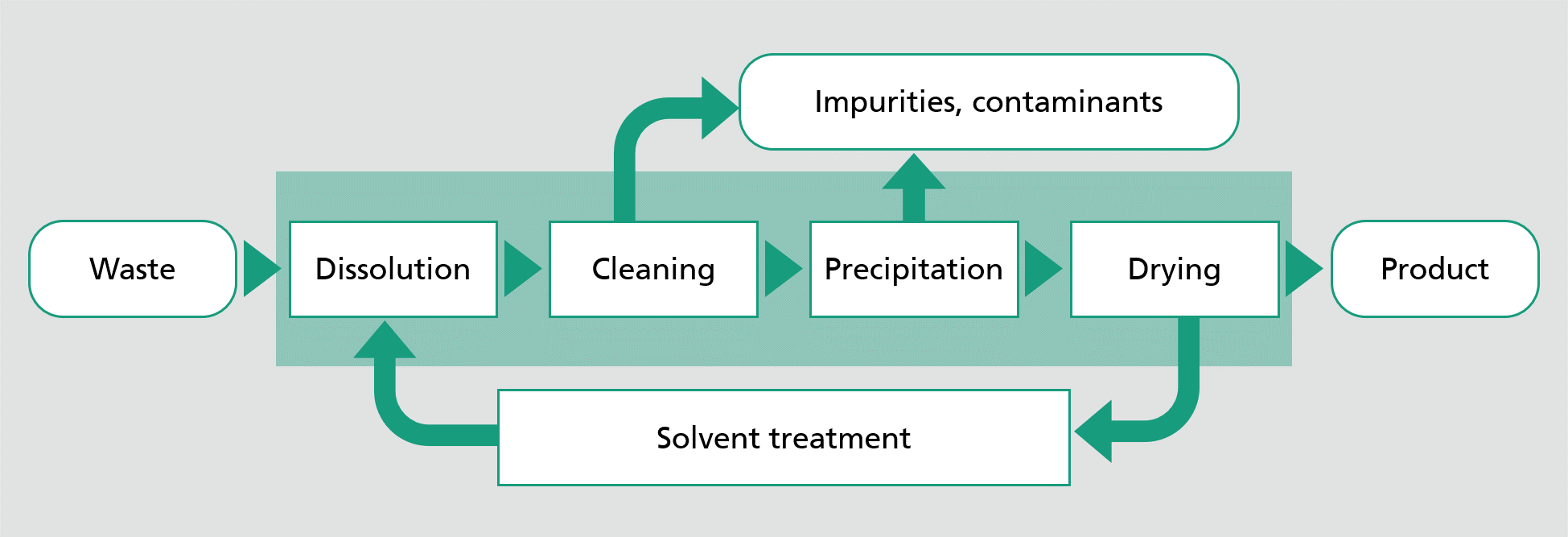

Solvent-based recycling is working as a multi-step process which integrates different unit operations outlined in the figure below. First, target polymers are selectively dissolved out of waste mixtures and composites. In this respect dissolution refers to a physical dissolution without a chemical interaction of the solvent with the polymer chain, which keeps intact in the course of the process. Secondly, undissolved components are mechanically separated while dissolved undesirable substances such as printing inks, additives, and pollutants are effectively separated by special purification steps on a molecular level. Finally, the purified target polymers are being separated from solvents, dried, and are now ready to be used for new production processes.