Plastics of tomorrow - What should they be like?

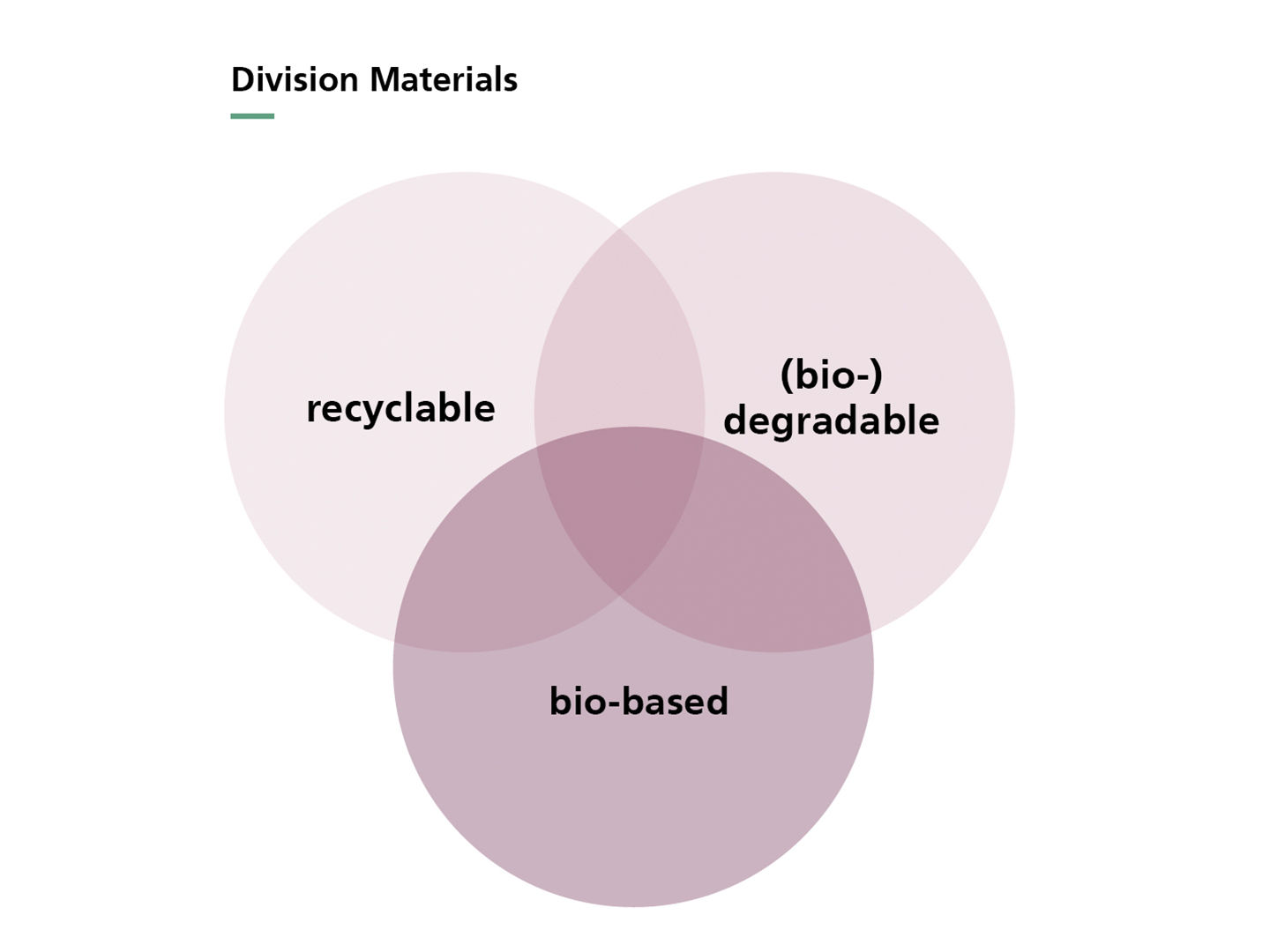

It is hard to imagine everyday life without plastics. Due to low prices, easy processing and great variety of properties, they conquered many applications. However, they also have their downsides, because rising plastic waste increasingly pollutes the environment. Their contribution to the climate crisis is another negative side of the material. In our online workshop, we will discuss what tomorrow's plastics should be like: recyclable, bio-based or degradable – and what these properties are all about.

Sustainability and climate change prevention have become strategic goals of today's corporate policies. The demands placed on new plastic products are increasing: Their raw materials should come from sustainable production and they must be durable, reusable, recyclable and, if possible, repairable. What new approaches and solutions are coming from plastics research? How do these approaches compare?

In 2015, the plastics industry was responsible for 1.7 gigatons (Gt) of carbon dioxide equivalent emissions1, according to data from Zheng and Suh2. This represents about 4 percent of global emissions at that time. The authors predicted that if the amount of plastics consumed continued to increase by about 4 percent per year, approximately 1,600 million t/a would be produced in 2050 and that its carbon footprint would already be 6.5 Gt.

Recently, more detailed calculations published by Cabernard et al. 3 concluded that the current trend is even more dramatic. This is due to the shift in plastics production to countries with a high percentage of coal-fired power. After all, 6 percent of the world's coal-fired electricity is needed for plastics production. Therefore, the authors indicate already 2.0 Gt of CO2 equivalent emissions for the year 2015.

What can the plastics industry do to avoid being one of the biggest CO2 emitters in the future after defossilization4 of other industrial sectors? Zheng and Suh considered four options for this:

1) Use of renewable energy in plastics production and processing.

2) Reduction of the increase in material consumption to 2 percent per year.

3) Complete switch to bio-based plastics.

4) Mechanical recycling of all plastic waste.

A very large effect has the first measure. However, that alone would not lead to a reduction in overall emissions, even if future plastics consumption was reduced. Only if the plastics industry switched to using significantly more bio-based raw materials in the future and if recycling rates were increased as much as possible, emission reductions would be achieved. For this reason, the requirements for new plastic products are increasing rapidly: Their raw materials should come from sustainable production and they must be durable, reusable, recyclable and, if possible, repairable.

New developments in recent years have significantly expanded the potential applications of bio-based plastics. The properties of poly(lactic acid) (PLA), for example, have been optimized so that the material can be used in technical components such as electronics housings. Special chemical modifications open up applications for polymers such as PLA or polyhydroxyalkanoates (PHAs)5 in the field of adhesives. The quality of recyclates can be improved by adapted processing methods and the use of innovative additive combinations. In this context, chemical recycling is attracting more and more interest as an alternative to mechanical recycling, as it enables the production of high-quality plastic recyclates.

Experts from CCPE research and industry will report more on bioplastics as a sustainable alternative and on the possibilities of recycling plastics and producing high-quality plastic recyclates at the Fraunhofer CCPE Compact online workshop on February 24.

Registrations are still possible until February 17 at:

Contact persons:

Office Fraunhofer CCPE

c/o Fraunhofer Fraunhofer UMSICHT | Osterfelder Str. 3 | 46047 Oberhausen

Dr. Hartmut Pflaum (Hartmut.Pflaum@umsicht.fraunhofer.de, Tel. +49 208 8598-1171)

Dr. Stephan Kabasci (Stephan.Kabasci@umsicht.fraunhofer.de, Tel. +49 208 8598-1164)

________________________________________________________________________________

1) CO₂ equivalents (CO₂) are a unit of measurement for standardizing the climate impact of the different greenhouse gases. (https://www.myclimate.org)

2) Zheng und Suh, University of California, doi.org/10.1038/s41558-019-0459-z

3) Cabernard et al, ETH Zürich, doi.org/10.1038/s41893-021-00807-2

4) The term defossilization describes the conversion of an economy with the aim of replacing fossil energy sources with renewable alternatives. (https://www.forschungsnetzwerke-energie.de)

5) Polyhydroxyalkanoates (PHA) are naturally occurring water-insoluble and linear biopolyesters formed by many bacteria as reserve materials for carbon and energy. (https://de.wikipedia.org)