Annealing as a possibility for optimized material recycling of thermoformed plastic products using the example of PLA (disposable beverage cups) and evaluation using life cycle (gap) analysis.

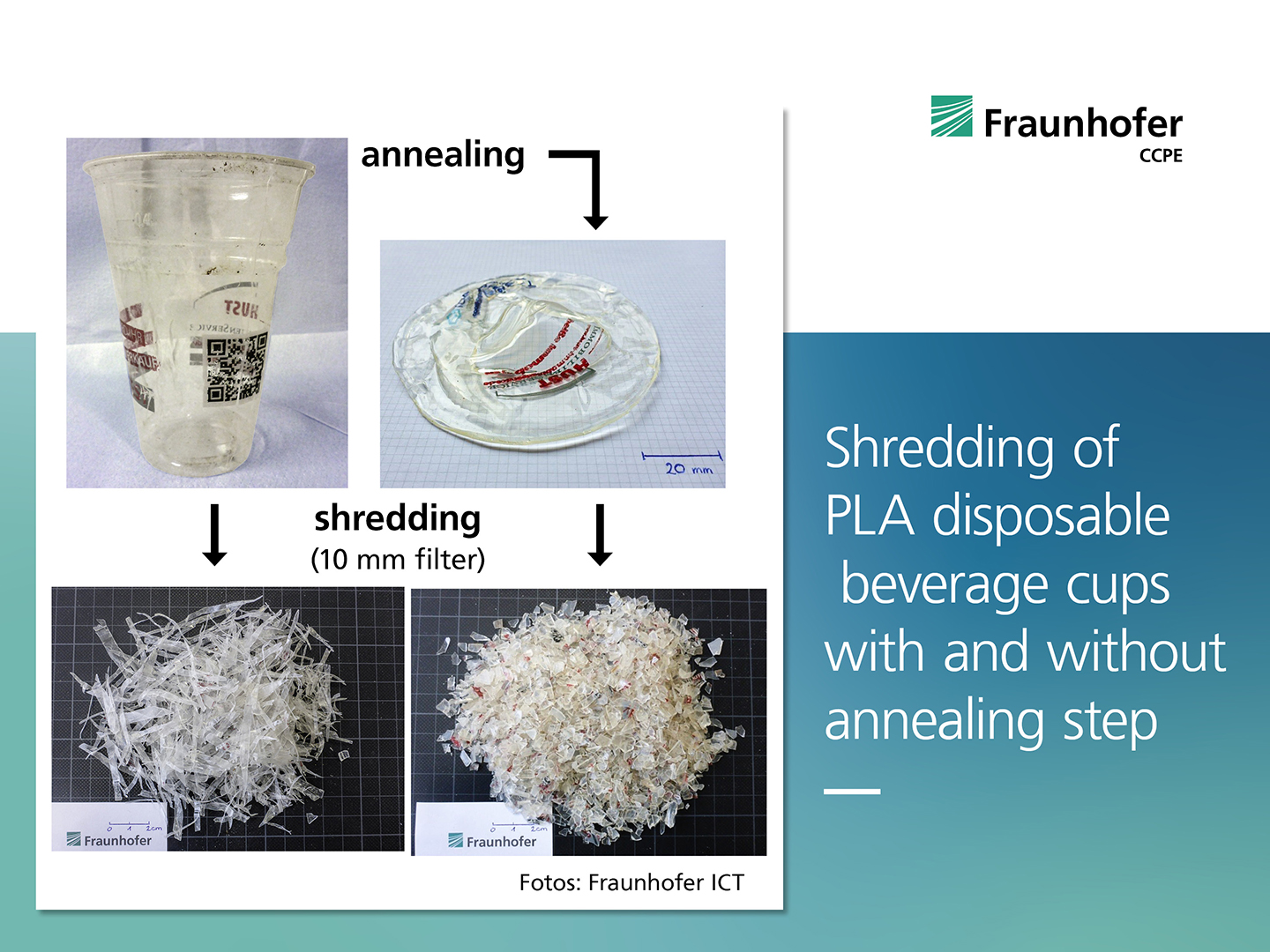

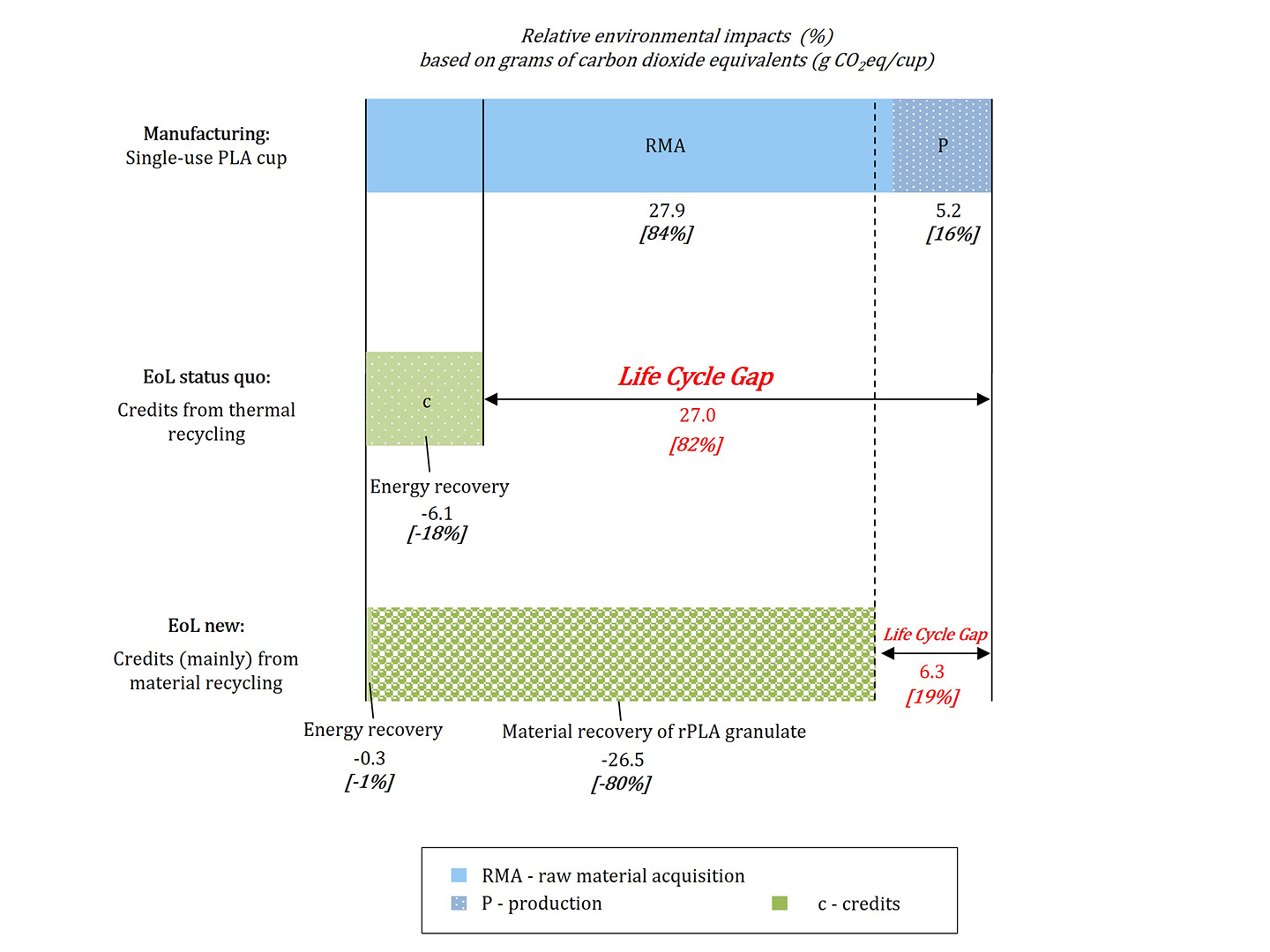

To enable effective material recycling of the biopolymer poly(lactic acid) (PLA) from disposable beverage cups, the ordinary process chain for mechanical recycling of plastics (washing, shredding and recompounding) was extended by integrating an additional annealing step. The thermal pretreatment, which leads to a relaxation in the molecular structure of the biopolymer, enables the PLA material to be subsequently comminuted with less energy input (total energy savings > 10%) and to generate flakes that exhibit improved flowability for further processing (production of rPLA pellets using an extruder). This makes it possible to recover PLA in new-product quality and significantly reduce the corresponding life cycle gaps (LCGs) (> 60%, see Fig. 1). A pictorial comparison of the materials with and without annealing step is shown in Fig. 1. The considered disposable cups are examples of thermoformed products. From an engineering point of view, it is in principle conceivable to test the additional process step of annealing prior to shredding on other products and thermoplastic polymers as well. Thus, any thin-walled component, such as PET bottles or thermoformed trays, could be subjected to additional thermal treatment before shredding in order to achieve higher process efficiency by means of an optimized molecular structure of the polymer and to further reduce the gaps in the cycle in an energy-efficient manner.