Recyclates that do not smell – we show how it’s done

Newsletter 02/2020

Many subtle messages play a role in customers’ purchase decisions. Odors and emissions are such factors, which, along with haptics, are an essential component for product success. CCPE researchers are therefore working on the reduction of odors and emissions from recycled plastics.

Customers often make purchasing decisions unconsciously. Many subtle messages play a role and have an influence on the consumer’s buying behavior. Successful companies take advantage of this by influencing them in a targeted manner and thus gain an edge over the competition. Odours and emissions are such factors, which, along with haptics, are an essential component for product success.

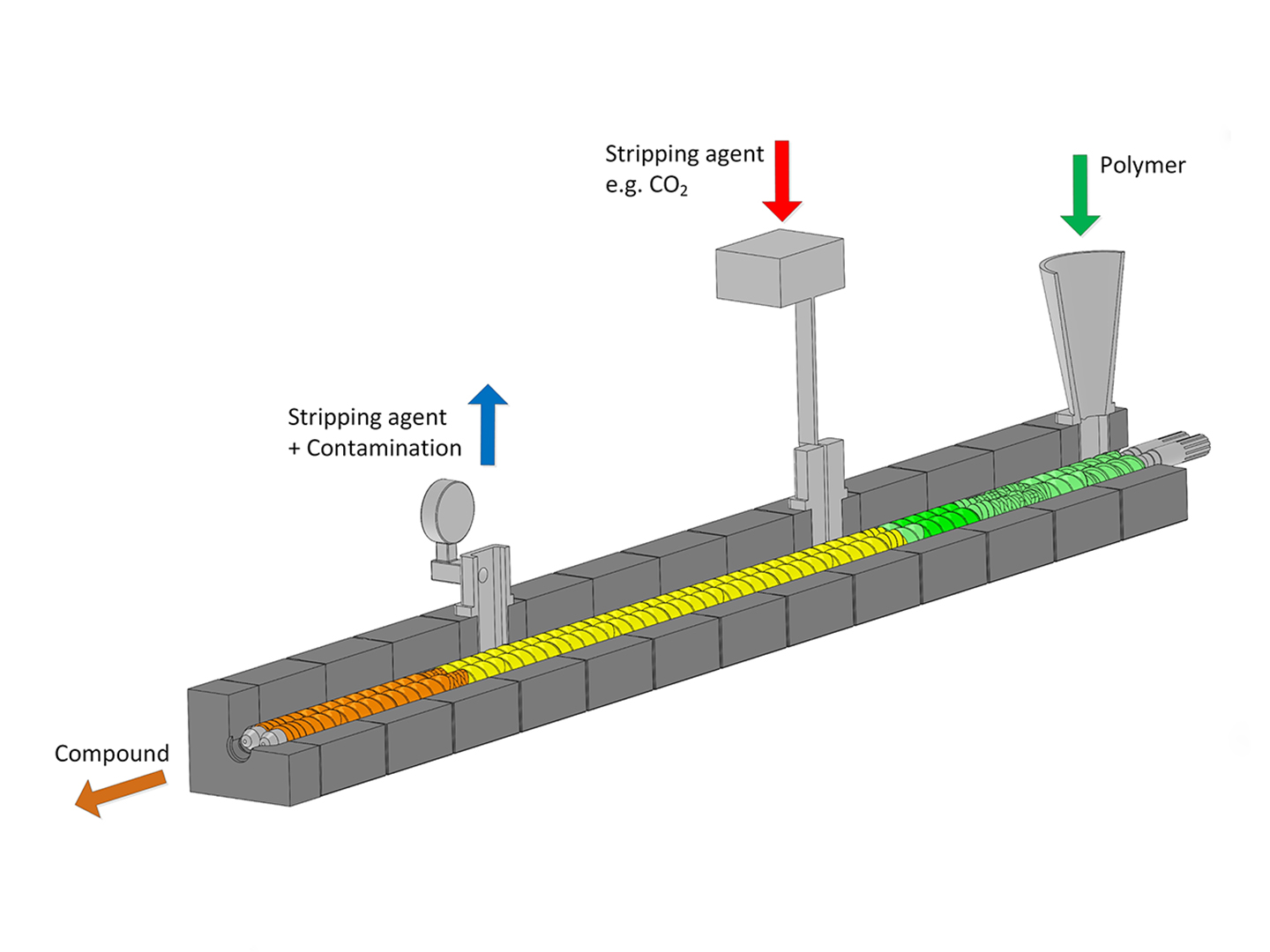

CCPE researchers are working intensively on solutions to reduce odors and emissions from recycled plastics for various products. The continuous purification process developed during the compounding process enables this to be done efficiently and economically. Depending on the application and optimization goal, odor and emission reduction is achieved either with entrainer-assisted degassing or extractive extrusion. Depending on the contamination to be removed, the process can be very easily integrated into an existing compounding plant. The “cleaned” granulate is then used to produce, for example, high-quality plastic components for car interiors that meet very strict emission requirements. Plastic waste with a strong odor can be further processed by odor neutralization not only into “cheap garbage bags” as before, but also into higher quality films. In general, odour neutrality, even for products of daily use, opens up the potential for new groups of buyers.