Fraunhofer CCPE at the K trade fair

Sustainable plastic packaging, cascading recycling or the degradation behavior of films

Since 2018, Fraunhofer CCPE has been researching how the plastics value chain can become circular. At the K trade fair from October 19 to 26, Fraunhofer CCPE will present promising developments for a successful transformation from a linear to a circular plastics economy. In Hall 7, booth number 70SC01-3, interested parties can learn more about, for example, the web-based self-check tool CRL® , a sustainable reusable transport box, cascading recycling, circular product design or the degradation behavior of films.

In the Fraunhofer Cluster of Excellence Circular Plastics Economy CCPE, six institutes of the Fraunhofer-Gesellschaft develop system services and product innovations for a sustainable circular plastics economy together with partners from industry. This is because we are still stuck in a linear plastics economy worldwide, recycling systems are inefficient, and only a few plastic recyclates achieve such a high quality that they can become new products. The cluster is now presenting current research results at K.

Self-Check Tool CRL®

The web-based self-check tool Circular Readiness Level® has already established itself. With its help, companies can subject their products, services or business models to a self-test for circularity. It provides answers to questions such as: What is the product's multifunctionality, repairability or dismantlability? Is end-of-life recyclability possible? Does the product consist of secondary, renewable or biodegradable plastics? In a second step, companies receive an assessment of the Circular Readiness Level® of their product as well as recommendations for further steps.

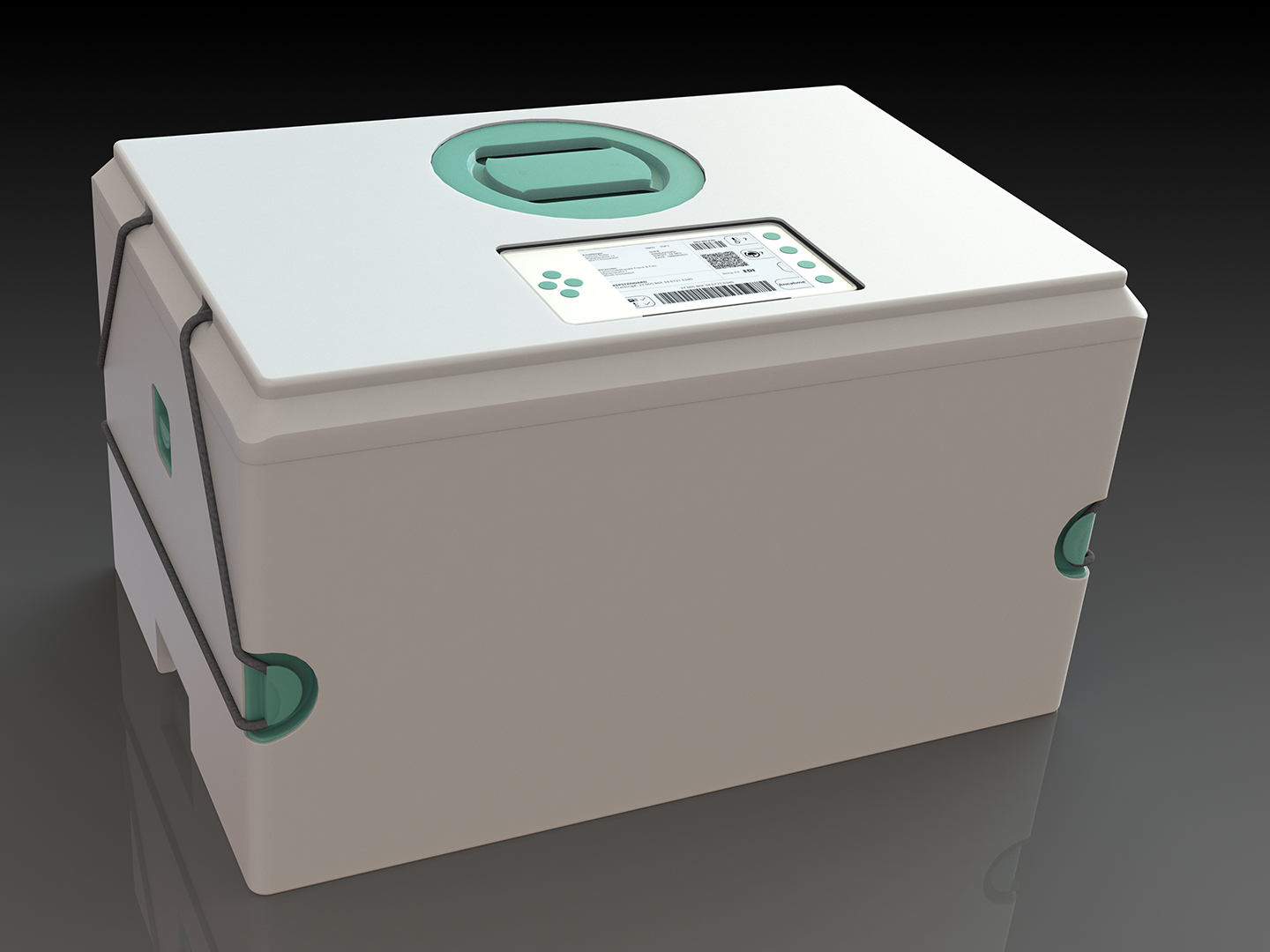

Demonstrator: Reusable transport packaging

With the reusable transport packaging for B2C food shipping, Fraunhofer CCPE demonstrates a sustainable plastic packaging that combines potentials of circular plastic compounds with innovative manufacturing processes for component production. In addition to the innovative monomaterial approach from newly developed bio-based polylactide (PLA) particle foams, systems for traceability through integrated sensor technology and an associated digital twin will be presented. The collected data brings added value for the customer, e.g. to prove an unbroken cold chain, and it enables pooling system operators to perform valuable analyses for logistics and business model optimization as well as for the right R strategy - based on aging effects of the plastics.

Technology cascade for recycling

Furthermore, Fraunhofer CCPE presents the concept for an optimized recycling cascade for plastic waste that can no longer be recycled by conventional, mechanical processes, e.g. mixed packaging waste, shredder residues or composite materials. The input materials are pre-sorted by AI and treated via a combination of three innovative recycling technologies. According to this concept, the quality of the plastic recyclates is significantly improved and the product yield is increased.

Test stand for degradation tests of plastics

The Fraunhofer CCPE researchers developed a test rig that investigates the artificial aging of films or other plastic products on soils under the influence of UV radiation, humidification and temperature - and also in combination. In this way, it is possible to observe under realistic conditions which phases a biodegradable plastic product goes through and how the product's properties change during its life cycle.

Fraunhofer CCPE at the K 2022 trade fair

Hall 7, booth number 70SC01-3

Are you already interested in an exhibit?

Please feel free to make an appointment with us.

Last modified: